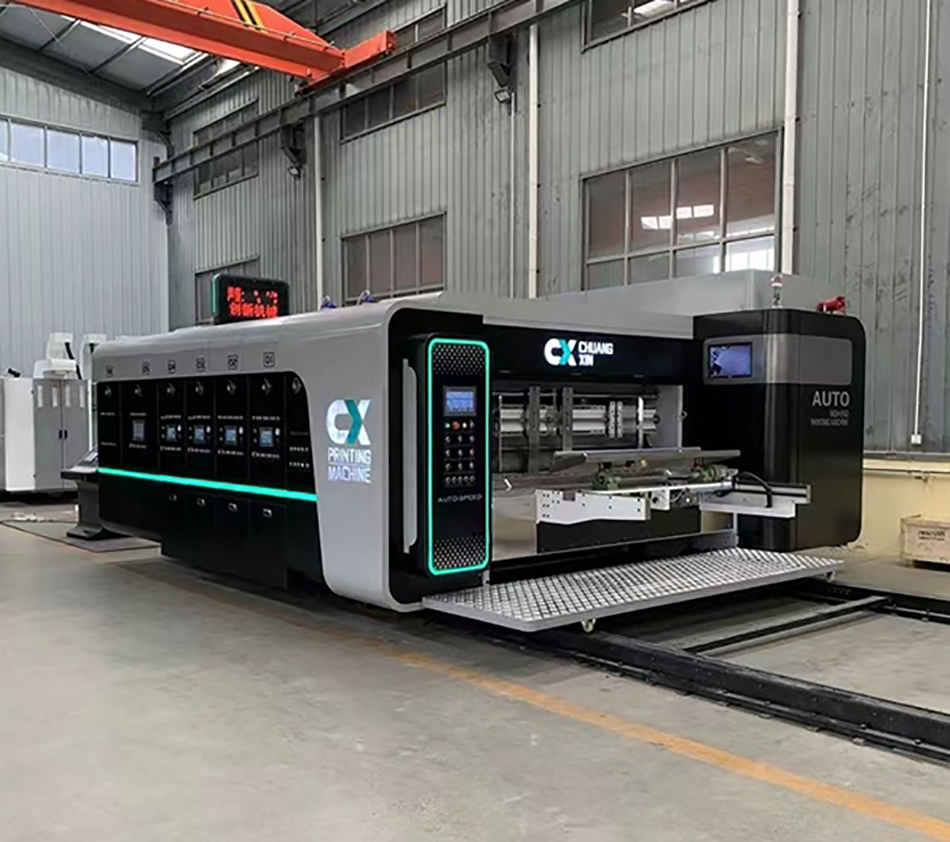

Fully Vacuum Adsorption Corrugated Printing Slotting Die Cutting Carton Box Printer Cardboard Machinery

1 Feeding unit

* Servo lead feeder system, vacuum adsorption transmission, frequency controlof air flow, increase the stablity and accuracy of paperboard conveying.* Fast-changing paperfeeding cot mechanism, wrapped with soft rubber, durable.easy maintenance of equpment

* Air sucion and dust reoval system can remove a large amount of paper dust on thesurface of cardboard and improve printing quality.

2 Printing unit

*Full vacuum adsorption ,with ceramic feeding wheel transfrtsyatem.*Frequency conversion adjustment ads orption air,also accordingto the lengthof the cardboard automatically adjust the damper switch.*Quick replacement of rubber roller,anilox roller device,with fast replacementof suppirt

3 Slotting unit* Slotting knife wheel form: double knife single shaft type.* Aloy steel materiats of heat-treatment grinding saw tooth slot blade, Betterhardness and toughness.

*Pre-creasing transfer, the pre-creasing wheel surface wrap rubber.To avoiddamage in the cardboard.

* Creasing wheel inside embedded rubber, creasing wheel transverse moveposiion can be adusted with slotting knife holder at the same time.

4 Die cuting unit

*Equipped with imported quick change type polyurethane rubber, easy to chanigo, withone-way clutch as linear velocity compensation function, Ensures the rubber wear beforeand wear after die cutout the cardboard is same.* Die-cutting roller horizontal computer control, electric adjustment, amplitude modulation+10mm.

* Rubber roller mat correction mechanism to increase the number of times the pad is usedand reduce consumption.

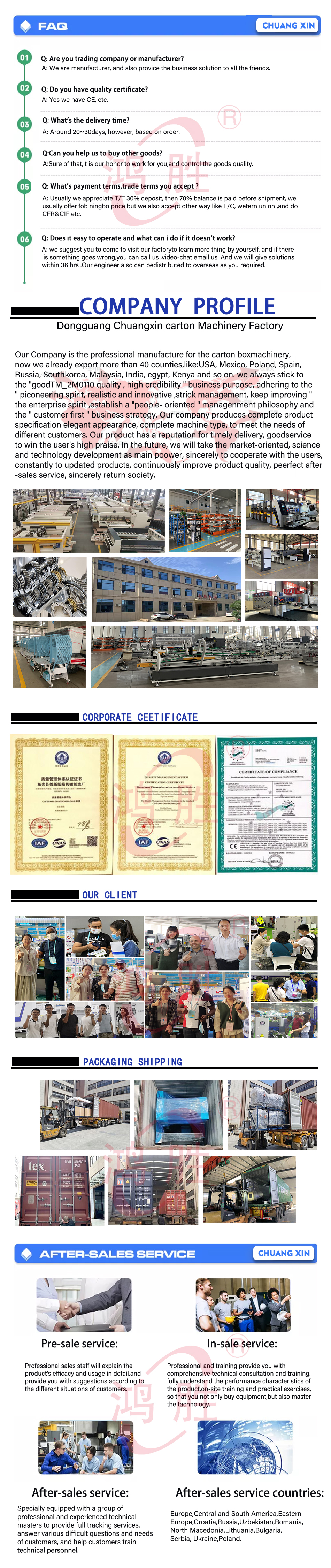

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory

Hebei Dongguang County ChuangXin Carton Machinery Manufacturing Factory